If you’ve visited Battleship IOWA, you’ve seen a mysterious gang of blue-coverall-clad personnel milling about, crawling in and out of odd spaces, appearing and disappearing seemingly at random, and doing a lot of mumbling and laughing.

They’re our Ops team, and we think they’re pretty great.

Maintaining all 887 feet and 45,000 some odd tons of Battleship IOWA is no easy task. This group is responsible for painting, electrical systems, welding, chasing rust, repairs, carpentry, even the building of new exhibits.

Need a large piece of equipment hoisted onto the ship? Ops will get it done. Want to adjust a deceivingly-heavy dockline? Call Ops!

They’re the small but intrepid force that has to handle the load once carried by a thousand young sailors.

[embedyt] https://www.youtube.com/watch?v=xYZ950JcX_w[/embedyt]

Getting these guys and gals to slow down long enough to pose for a photo is a challenge. They’ve got grubby business to take care of and they always want to get at it.

Prevailing upon them to stop and talk about how they feel about the ship is even trickier. We did manage to corral a few of them willing to drop some insights, though.

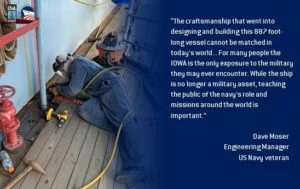

Chief Dave Moser

This navy veteran was making masks look cool long before COVID. He’s Battleship IOWA’s engineering manager and if you visit the ship, there’s a fairly good chance, you’ll see him in the trenches wielding a welding torch, ensuring the ship is sound and pretty.

He knows that even after more than seventy-five years, she still has a mission in this world and he’s here to help her achieve it.

Mary Stoddard

The face behind the mask belongs to the master behind the paint. Mary is shy of recognition; she lets her work ethic do her talking – and it speaks volumes.

She remembers Battleship IOWA’s arrival to the Port of Los Angeles. She recalls looking up the channel at the approaching giant and thinking, “That’s not a warship – it’s a work of art!”

She is continually amazed that she gets to work on the ship, and she loves her job. If you ask her about it, her face glows as she details the process of preparation, then the layering of just the right amount of paint to make this grand dame look beautiful. She feels immense satisfaction, both in a task well done and in being part of the IOWA family.

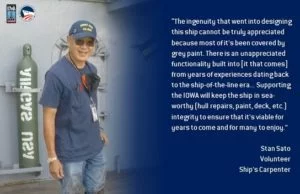

Stan Sato

…is obsessed with teak. And Douglas fir. And several other types of wood. His repairs to IOWA’s decks are as attractive as they are functional, and nothing he has to remove goes to waste. If it doesn’t go back onto the deck, he’ll lovingly repurpose it into a gorgeous artifact for display.

His regard for the ship, her craftsmanship, and her place in history goes far beyond her decks.

These three individuals are only a few examples of the extraordinary crew that keeps Battleship IOWA afloat. Their task is monumental – from stem to stern and keel to masthead, their work space covers almost twenty stories and three football fields.

The logistics they face aren’t their only challenge. They’re also constrained by funding – now more than ever.

Anyone involved with this ship will tell you – usually without being prompted – how important it is to preserve her. As both Stan and Chief Moser mentioned, the craftsmanship that went into her creation cannot be replicated today.

The ship was designed with slide rules and forged without computer-controlled machinery. It is a wonder of engineering that must be experienced to be valued as highly as it should.

And that’s just the physical ship. The stories she has to relate are equally compelling. From presidents to ordinary sailors who spent spans of their lives trusting her to protect them while they protected us to the current crew that is dedicated to sharing everything about this mechanical marvel, Battleship IOWA is an outstanding treasure that must remain open for generations to come.

Your support makes all this possible!